The value of dtf printing in t-shirt DIY

August 2, 2024

The value of dtf printing in t-shirt DIY

Introduction

Direct-to-Film (DTF) printing is changing the game for the DIY t-shirt market. With its innovative technology, it offers high-quality and long-lasting prints on various fabrics, making it a popular choice among t-shirt printing enthusiasts.

DTF printing stands out due to several key features:

- Versatility: The ability to print on multiple materials like cotton, polyester, and blends.

- No Pretreatment Required: Unlike Direct-to-Garment (DTG) printing, DTF doesn’t need fabric pretreatment, simplifying the process.

- Cost Efficiency: Uses less white ink compared to DTG, which reduces costs significantly.

- Durability: Prints withstand multiple washes without cracking or peeling.

These characteristics contribute to the growing significance of DTF technology in t-shirt DIY projects. Adopting DTF printing can enhance both efficiency and creativity, making it a valuable choice for anyone looking to venture into t-shirt design or expand their existing operations.

Understanding DTF Printing

Direct-to-Film (DTF) printing is transforming the DIY t-shirt market with its innovative and effective method. The DTF printing process begins by printing your design onto a special film using a direct-to-film printer. This film is then coated with a layer of adhesive powder, which is melted onto the design through a heat press. Finally, the film is pressed onto the fabric, permanently transferring the design.

Differences from Other Methods

1. Direct-to-Garment (DTG)

DTG printing directly applies ink to the fabric, requiring pretreatment to ensure ink adhesion. In contrast, DTF eliminates this step, reducing preparation time.

2. Screen Printing

Traditional screen printing involves creating stencils for each color, making it labor-intensive and less cost-effective for small orders. DTF allows for detailed, multicolor designs without extensive setup.

Eco-Friendly Inks

DTF printing stands out with its use of eco-friendly inks. These inks are water-based and free from harmful chemicals, aligning with the industry’s shift towards sustainable practices. This not only makes DTF an environmentally responsible choice but also appeals to the growing consumer demand for green products.

By integrating these eco-friendly inks, DTF technology supports sustainability while delivering vibrant and durable prints. The combination of efficiency, versatility, and environmental consciousness makes DTF printing a powerful tool for DIY enthusiasts aiming to create high-quality t-shirts with minimal environmental impact.

Benefits of DTF Printing Technology

1. Versatility with Materials

One of the primary advantages of DTF printing is its compatibility with a wide range of fabrics. Unlike other methods, DTF can be applied to:

- Cotton

- Polyester

- Blends

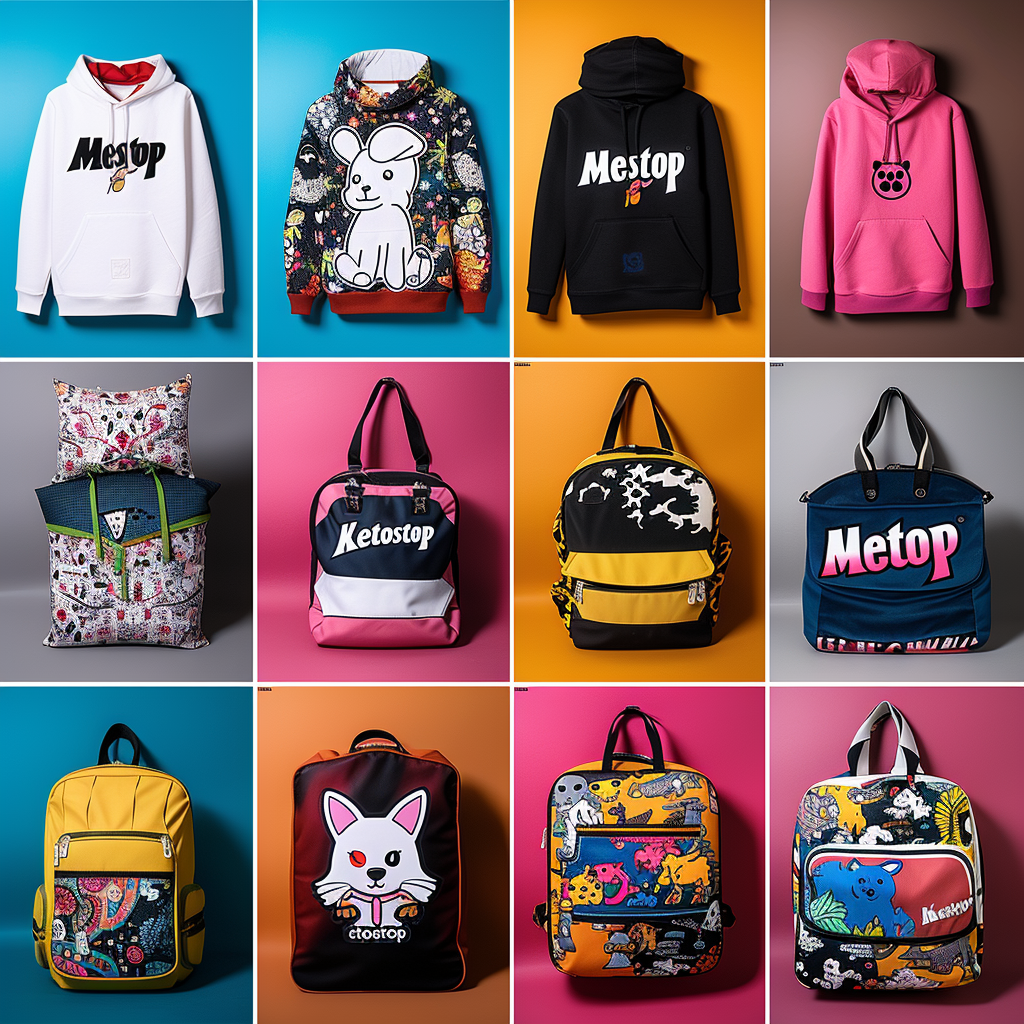

This versatility allows you to expand your creative horizons beyond just t-shirts. Imagine printing on tote bags, hoodies, or even pillowcases. The ability to work on various materials means you can diversify your product line effortlessly.

2. Cost-Efficient Printing

When comparing DTF to DTG and screen printing, cost-efficiency becomes a significant factor. Here’s why:

- Reduced Ink Usage: DTF uses significantly less white ink, which is often the most expensive component in printing. This reduction in ink usage translates to lower costs per print.

- No Pretreatment Required: Unlike DTG, which requires a pretreatment process that adds both time and cost, DTF eliminates this step entirely. This simplification not only reduces expenses but also speeds up production times.

For small businesses or individuals starting their own t-shirt line, these cost-saving elements make DTF an attractive choice. Lower operational costs mean higher profit margins and more competitive pricing for your products.

3. Durability

DTF prints are known for their durability. They withstand multiple washes without cracking or peeling, making them ideal for items that will see heavy use. This durability adds value to your products, ensuring customer satisfaction and repeat business.

4. Fast Production Times

With no need for pretreatment steps, DTF printing accelerates the production process significantly. Quick turnaround times are especially beneficial for handling small orders or meeting tight deadlines.

The combination of versatility, cost-efficiency, and durability makes DTF printing technology a valuable asset for any t-shirt DIY enthusiast or small business owner looking to produce high-quality products efficiently.

Simplifying the T-Shirt Printing Process with DTF

DTF printing stands out by eliminating the need for pretreatment steps, making it a highly user-friendly option, especially for beginners. Traditional methods like DTG require pretreatment of fabrics, which can be time-consuming and labor-intensive. DTF bypasses this step entirely, streamlining the process and reducing preparation time.

Ease of Application

One of the most appealing features of DTF printing is its ease of application. The process involves printing your design onto a special film, which is then transferred to the fabric using heat. This method allows you to apply designs to hard-to-reach areas or awkward surfaces that would be challenging with other printing techniques.

- User-Friendly: Perfect for those new to t-shirt printing.

- Versatile: Allows for application on various types of fabrics and surfaces.

- Efficient: Simplifies the entire printing workflow.

Faster Production Times

By cutting out the pretreatment step, DTF significantly reduces production times. This makes it ideal for small orders or projects requiring quick turnaround times. Whether you’re working on a custom order or preparing inventory for a busy season, DTF ensures you can keep up with demand without sacrificing quality.

- Quick Turnaround: Enables faster delivery times.

- Less Downtime: More efficient use of your time and resources.

- Scalable: Easily manage both small and large orders.

DTF technology offers practical solutions that make t-shirt printing accessible and efficient for everyone, from hobbyists to small business owners.

Investing in Your Own Direct-to-Film Printer: What You Need to Know

Choosing the best DTF printer for small business owners requires careful consideration of various models and their features. Notable options on the market include the ProColored DTF printer and the L1800 DTF printer.

Popular Printers for Small Businesses

1. ProColored DTF Printer

- Known for its high-quality prints and reliability.

- Features advanced ink systems that ensure vibrant colors and sharp details.

- Suitable for both small businesses and individuals due to its user-friendly interface.

2. L1800 DTF Printer

- Offers a balance between affordability and performance.

- Capable of handling various fabric types, making it a versatile choice.

- Compact design, ideal for limited workspace setups.

Key Factors to Consider

When investing in DTF printing equipment, consider the following factors:

1. Print Quality

- Look for printers that can deliver high-resolution images with precise color accuracy.

- Ensure the printer supports a wide color gamut to produce vibrant designs.

2. Speed

- Evaluate the printing speed, especially if you aim to handle bulk orders or time-sensitive projects.

- Faster printers can enhance productivity and reduce turnaround times.

3. Ease of Use

- Choose printers with intuitive software interfaces and straightforward maintenance processes.

- User-friendly models minimize learning curves, making them ideal for beginners.

Investing in the right DTF printer can significantly impact your business’s efficiency and output quality. By selecting a model that aligns with your specific needs, you can streamline your t-shirt printing process and achieve professional results.

In-House Printing vs Outsourcing: Finding the Right Balance for Your T-Shirt Business

Choosing between in-house vs outsourced printing options can significantly impact your t-shirt business.

Advantages of In-House Printing

- Control Over Quality: Having your own DTF printer allows you to oversee every aspect of the production process, ensuring high-quality prints that meet your standards.

- Design Flexibility: You can experiment with new designs freely and make immediate adjustments without waiting for third-party approval.

- Quick Turnaround: With in-house printing, you can respond swiftly to urgent orders or market trends.

Potential Downsides

- Limited Scalability: Managing large volumes can be challenging if you’re handling the entire printing process yourself.

- Initial Investment: High upfront costs for purchasing equipment and materials might be a deterrent for some small businesses.

Considerations for Outsourcing

- Cost Management: Outsourcing can help manage expenses by allowing you to scale production without significant capital investment.

- Focus on Core Activities: By delegating printing tasks, you can concentrate on other crucial aspects of your business such as marketing and customer service.

- Access to Expertise: Professional printing services may offer advanced techniques and higher-quality results that are difficult to achieve in-house.

Exploring Practical Applications of DTF in T-Shirt DIY Projects

Direct-to-Film (DTF) printing opens up a world of possibilities in custom apparel design with vibrant prints. This technology allows for the creation of intricate and unique designs that can cater to personal style or commercial branding. Whether you’re an artist looking to bring your artwork to life on fabric or a small business aiming to offer customizable merchandise, DTF printing provides the flexibility needed.

1. Personalized Gifts

Create one-of-a-kind t-shirts as gifts for friends and family, featuring custom designs that reflect their interests and personalities.

2. Brand Merchandise

Develop branded apparel with high-quality prints that can withstand multiple washes, making them perfect for promotional items.

3. Artistic Expression

Turn your digital art into wearable pieces, offering fans a tangible way to support and showcase your work.

4. Event-Specific Apparel

Design themed t-shirts for events like weddings, reunions, or corporate gatherings, ensuring each piece is unique and memorable.

The ease of application and ability to print on various materials make DTF a versatile choice for anyone interested in custom apparel design with vibrant prints. This technology enhances creativity by providing the tools needed to produce detailed and durable designs effortlessly.

Conclusion

Investing in a quality direct-to-film printer like the ProColored or L1800 model can transform your DIY t-shirt projects. By understanding the advantages of direct-to-film technology, including versatility, cost-effectiveness, and durability, you can effortlessly create high-quality, one-of-a-kind designs. Whether your goal is to start a small business or boost your personal creativity, adopting DTF printing will keep you ahead in the ever-changing t-shirt industry.

Blog, News direct transfer film, dtf film, dtf powder, dtf printer, dtf printing, erasmart, Printer

Discover the Power of EraSmart’s A4 Roll DTF Printer L805

Discover the Power of EraSmart’s A4 Roll DTF Printer L805